Vietnam pushes co-processing to cut plastic waste, coal reliance and reduce emissions

Vietnam is scaling up co-processing in cement kilns to tackle non-recyclable plastic waste, reduce coal dependence, and advance its circular economy and net-zero 2050 goals.

THE HANOI TIMES — Applying co-processing technology in cement production can help Hanoi and other major cities handle up to 70,000 tons of daily waste and reduce dependence on waste-to-energy plants.

This method uses waste as an alternative material or fuel in industrial production, particularly in cement kilns. It effectively treats non-recyclable waste while cutting reliance on traditional raw materials.

It also helps Vietnam reduce coal consumption, prevent plastic leakage into the ocean, and contribute to the net-zero goal by 2050, bringing both environmental and economic benefits.

Growing pressure from waste, especially plastics

According to Hoang Thanh Vinh, a representative of the United Nations Development Program (UNDP) in Vietnam, the country generates about 70,000 tons of solid waste per day.

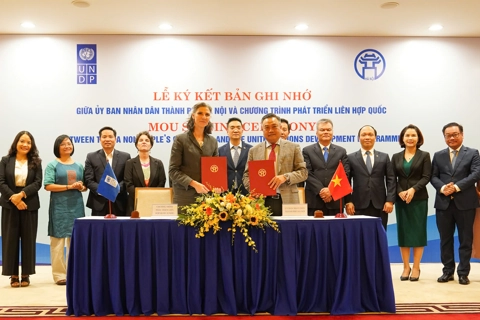

An overview of the workshop “From Pilot to Policy: Addressing Non-Recyclable Plastic Waste through Co-Processing in the Cement Industry”. Photo: Phi Nhat/The Hanoi Times

Hanoi produces around 7,500 tons daily, and Ho Chi Minh City about 14,000 tons. Urban areas account for 60% of the total, while rural areas contribute 40%. Waste volumes are expected to rise by 10%–15% annually in the short term.

Vietnam spends around US$3.35 million each day, or nearly US$1.2 billion annually, on waste collection and treatment. Landfilling remains the main method, accounting for 64%, followed by composting (16%) and waste-to-energy incineration (12.7%).

Despite ongoing campaigns to reduce plastic waste such as Hanoi’s plan to phase out single-use plastics, consumption continues to increase due to social demand, especially after the Covid-19 pandemic and the boom in online delivery services.

According to SINTEF, an independent research institute based in Norway, each Vietnamese consumes about 40 kilograms of plastic annually, 10 times higher than in 1990.

The country generates over 3.5 million tons of plastic waste each year, with 60%–70% going to more than 1,180 landfills, most of which fail to meet sanitary standards.

Vietnam recycles only about 20% of its plastic waste, mostly PET (beverage bottles, food packaging) and HDPE (plastic bottles, cans, pipes), while most soft plastics remain untreated.

“Informal workers and collectors gather most valuable plastics, but the rest, especially low-value ones, still go to landfills, posing microplastic and pollution risks,” said Vinh from UNDP Vietnam at a workshop this week.

He added that waste-to-energy projects are expanding rapidly, but household waste sorting still faces many challenges and requires stronger government action.

Vinh noted that co-processing currently focuses mainly on industrial and hazardous waste, while municipal solid waste remains largely untreated, even though logistics and transport conditions are favorable.

“Cement plants have strong demand and capacity for co-processing, while several waste-to-energy projects are under construction,” he said.

Palash Kumar Saha, Senior Advisor at SINTEF, warned that without decisive solutions, around 373,000 tons of plastic could enter the ocean annually, doubling by 2030 compared to 2018.

Vietnam now has seven operational waste-to-energy plants. The largest, in Hanoi’s Soc Son Commune, processes 4,500 tons per day, but their combined capacity reaches only 300 MW, far below the 1,400 MW potential.

Meanwhile, Vietnam’s cement industry has 61 factories and 87 kilns capable of co-processing waste. However, the thermal substitution rate (TSR) remains below 5%, except for some plants reaching 35%–40%.

Only 13–15 production lines are now licensed to co-process about five million tons of waste annually. The industry aims to raise the national TSR to 30% by 2050.

The OPTOCE project promotes co-processing

The “Ocean Plastic Turned into an Opportunity in Circular Economy” (OPTOCE) project, funded by the Norwegian Government and implemented in eight Asian countries over the past six years, has demonstrated that co-processing is a cost-effective, scalable, and environmentally friendly solution for Vietnam.

Hilde Solbakken, Norwegian Ambassador to Vietnam, speaks at the workshop. Photo: the Norwegian Embassy in Hanoi

Within this framework, the Lam Thach Green Cement Company (QNC) in Quang Ninh Province has pioneered co-processing in cement kilns.

At Lam Thach, low-value, hard-to-recycle plastics from Minh Khai Craft Village in Hung Yen Province and Trang Minh Village in Haiphong City were successfully co-processed in the company’s kilns.

Vietnam’s 82 active clinker kilns consume over 10 million tons of anthracite coal annually. Yet, the use of alternative fuels remains limited. The government aims to raise this share to 15% by 2030 and 30% afterward, showing vast potential for scaling co-processing across the country.

According to cement producer INSEE Ecocycle, co-processing in Vietnam is still in its early stage. This creates an opportunity for the cement industry to become a key player in solving the problem of non-recyclable waste while waste management infrastructure is still underdeveloped.

Experience from Lam Thach shows that co-processing can complement waste-to-energy incineration, reduce landfill use, and cut greenhouse gas emissions. For cement producers, it lowers fuel costs and supports sustainable growth.

“Its success proves that co-processing non-recyclable plastics in cement kilns is technically feasible, environmentally sound, and capable of creating large-scale impact,” said Dr. Kåre Helge Karstensen, OPTOCE Chief Scientist and Program Manager.

Norwegian Ambassador to Vietnam Hilde Solbakken affirmed that tackling marine plastics and climate change remains a top priority for Norway.

“Through OPTOCE, we have seen how science-based solutions like co-processing can turn plastic waste into a valuable resource that benefits the climate, economy, and communities,” she said.

She added that Norway remains committed to supporting this approach in Vietnam and the wider region, especially under the Just Energy Transition Partnership (JETP).

Despite progress, Vietnam still faces growing pressure from plastic waste and carbon emissions caused by rapid urbanization and increasing consumption. Many plastics continue to leak into rivers and seas, threatening ecosystems and coastal livelihoods, even as the country pursues its 2050 net-zero target under the JETP.

Dr. Karstensen said that the next step is to move beyond pilot projects and include co-processing in national policy to achieve lasting change.

However, challenges remain in policy making, financial incentives, and investment-ready models to promote the co-processing method in Vietnam.

Luong Duc Long, Vice Chairman of the Vietnam Cement Association, called for closer collaboration with environmental companies to turn waste into alternative fuel.

He urged the government to introduce incentives for businesses involved in co-processing.

“If we work together with determination, we can scale up this model, turning waste into ‘black gold’ and cement plants into sustainable co-processing hubs that build a greener, cleaner Vietnam,” said Long.